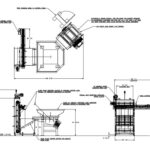

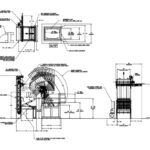

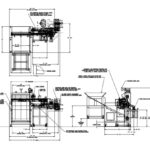

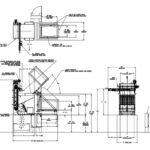

Heavy Duty Billet Feeder

Model 4800

Model-4800-Random-Load-“BILLET”-Feeder.pdf

Heavy Duty Billet Feeder Models

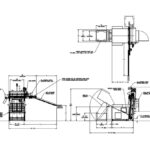

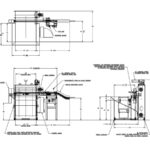

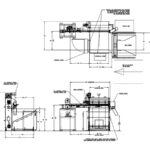

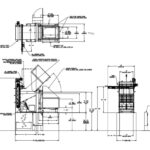

Model 4800 Random Load Heavy Duty Billet Feeder can handle billets up to 6” in diameter and lengths up to 30” long. Its unique design offers no part recirculation or part fall back. The feeder has been engineered so that it does not use vibration or gravity to manipulate the part orientation. This system has a variety of custom friendly attributes that were designed with increased productivity and decreased maintenance cost in mind. Some of the unique features include:

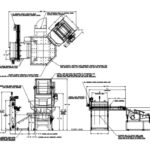

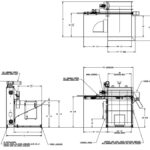

- A reversing motor on the cross-feed conveyor for part cleanout or part changeovers

- Adjustable or replaceable cleats to accommodate a broad range of part sizes and quick changeovers

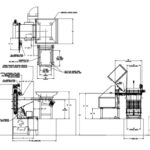

- Engineered to accommodate future re-tooling for added parts or new programs

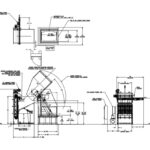

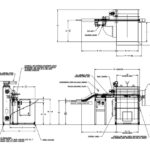

- Feedall can provide a hydraulic tub dumper or a motorized 180º roll-over dumper so loading parts is no problem

- Feedall can provide a metering hopper that takes all the initial impact of a full dump, increasing the life of the feed system

Heavy Duty Billet Feeders – 2000-3000-3600-4800

View 3D Model

Best viewed on desktop

Menu

Menu