Plug and play 2D robot guidance

Integrating flex feeding to your process shouldn’t require becoming a flex feeding expert – that’s why we’ve partnered with SICK to elevate your experience. Sequencing and control have been tested and refined to allow your engineers to focus on the bigger task at hand. Our team of part feeding experts

- Feeder, hopper, and backlight control pre-programmed

- Automatic part metering with configurable settings

- Easy to use web interface

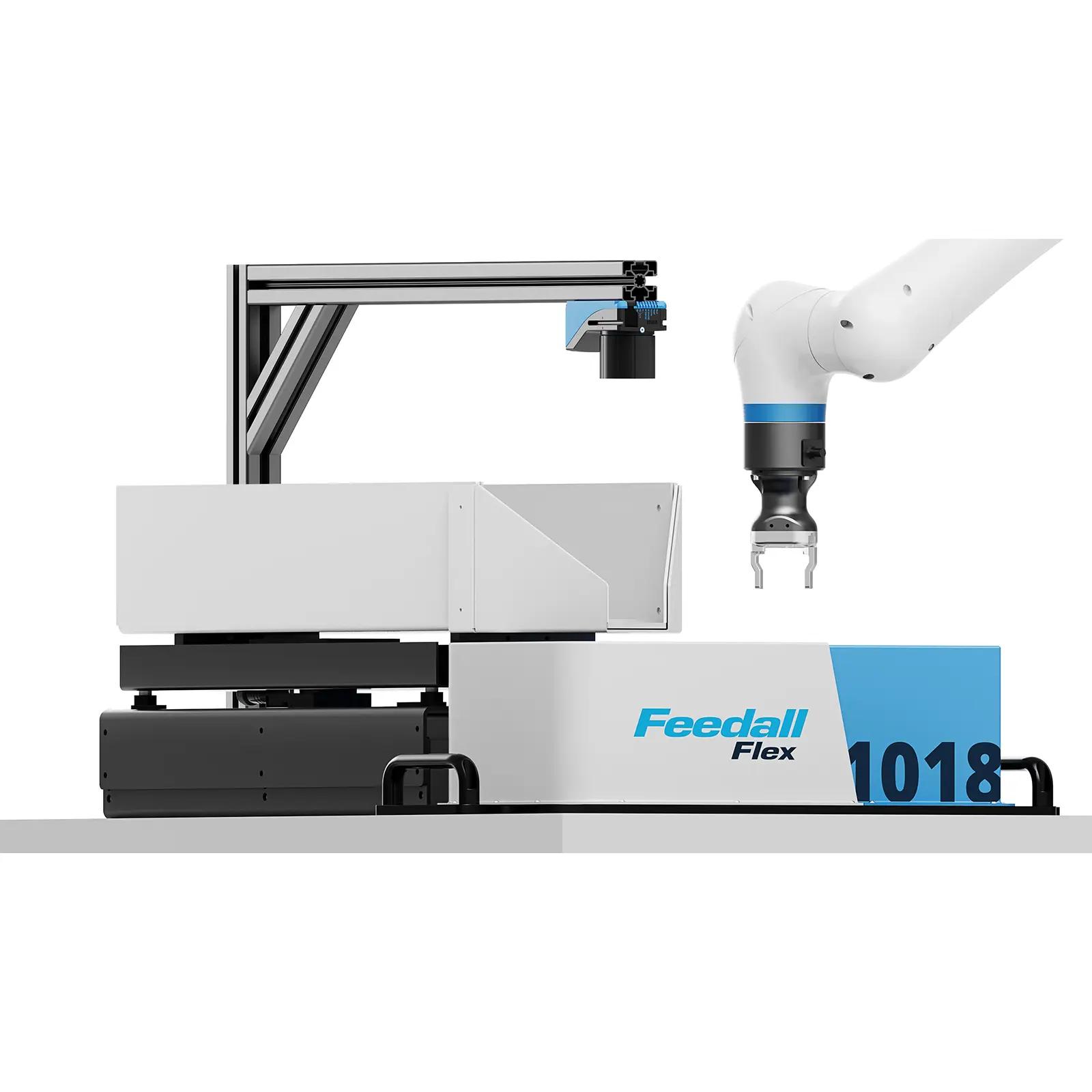

Overview

Powered by SICK PLOC2D, Guide-Eye is a compact, high-quality imager that provides a fast, cost-effective way to automate pick-and-place applications in any environment.

WHAT’S INCLUDED:

Feedall’s Guide Eye 2D vision software package is compatible with all industrial robots and allows for rapid setup of feeding cells.

It includes:

• SICK PLOC2D Camera

• SICK SIM Edge computing device

• Calibration aids

• Camera bracket

• All necessary cables

Even with no machine experience, setting up Guide Eye takes approximately 20 minutes.

SET UP THE SYSTEM

Bring your system online through the user account and adjust the focus and brightness of the camera

CALIBRATE THE CAMERA

Simply select the calibration target from the list and capture a

minimum of six imagesALIGN THE ROBOT

Achieve precise camera-to-robot coordination through our alignment workflow

CREATE A NEW JOB

Set up a new job (or multiple jobs) on the work plane and select a part reference point to accurately position the robot

ASSIGN THE FEEDER SETTINGS

Set the control drive according to the specifications listed on the startup worksheet

RUN PRODUCTION

With real-world coordinates for each detected part, you’ll have performance verification and accurate, reliable picking