Up to 50-inch long bars

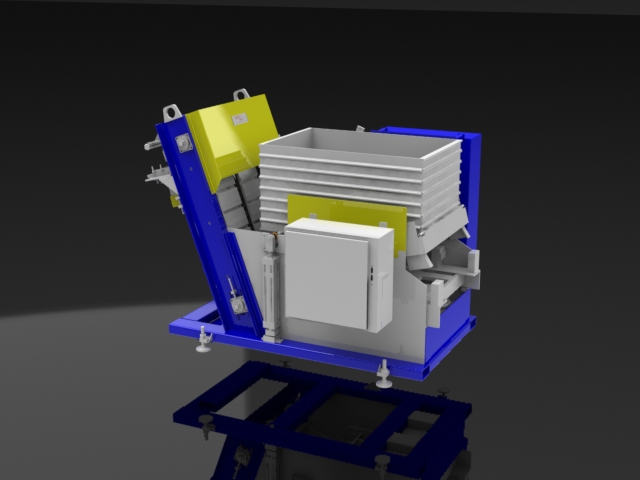

2250, 1775

When You Require a Long Bar Feeder, Turn to Feedall

For proper part feeding of long bars, tubes, and similar shapes, the specially designed Retriever 2250 and 1775 provide the capability you need — backed by our usual flexible options package and dedication to providing a finely-made piece of automation equipment.

An extension of our magazine loaded bar feeders, the 2250 and 1775 models are adept at feeding your longest parts into a host of secondary operations. The unit reduces the need for handling of bars and tubes, adding more efficiency to your production processes. While specialized around extended length parts, this model maintains the flexibility of being easily adaptable and integrated into your existing workflow.

Overview

The Retriever 1775 is a magazine-loaded long bar feeder and manipulates parts that exceed the 28-inch benchmark established by other models in this line. The unit automatically serves up parts for critical secondary operations through a design common to the Retriever series. Each bar or tube is singled out to an exit ramp, conveyor, or V-nest to provide exact part orientation and location.

Like all Feedall bar feeders, the Retriever 1775 can house additional options that streamline operation, ease integration, and add further functionality — such as heavy duty magazines and attached conveyor systems. Other available features include:

- Track and guide extensions

- Dual lifters

- Center supports for longer parts

- Dual cam shafts for better part flow

- Caster track for grinder wheel wear compensation

- Drip pans to return coolant back to machine

- Centering type discharge magazine

The Retriever 2250 is a floor-loaded long bar feeder and handles parts up to 50 inches in length. Low noise functionality is delivered by the zero-circulation design. Parts fed by this unit include steering racks, axle shafts, and many other bar & shaft shaped parts. The feeder works by elevating the parts on singular pads; they are then discharged rolling into a magazine. The parts then escape, rolling, to a cross conveyor, pusher device, walking beam, or customer tracking.

Each Retriever 2250 can be customized to best address your manufacturing needs. Options include:

- Easy access hopper side cut out for part loading (optional hinged door)

- Vertical elevator with two strands of roller conveyor chain

- Bolt-on cleat pads machined for each application part range

- Boston D.C. variable speed elevator drive

- Adjustable rear magazine and pneumatic escapement device

- Telescoping ramp from magazine to conveyor (for centerless grinder)

- Ball bushing conveyor mountings (for centerless grinder)

- Cross–Feed Conveyors

- Part Transfers, Qualifiers & Pushers

- Powered Wheels