Feedall Automation Serves this Critical Application with Specialized Solutions

Automation equipment dedicated to centerless grinding automation improves the rate of parts produced through one of the oldest machining processes in use. When cylindrical parts require a tight outer diameter tolerance over their length, a centerless grinding operation is often the manufacturer’s best option. Simply, a centerless grinder removes material from a part by passing it between spinning abrasive wheels.

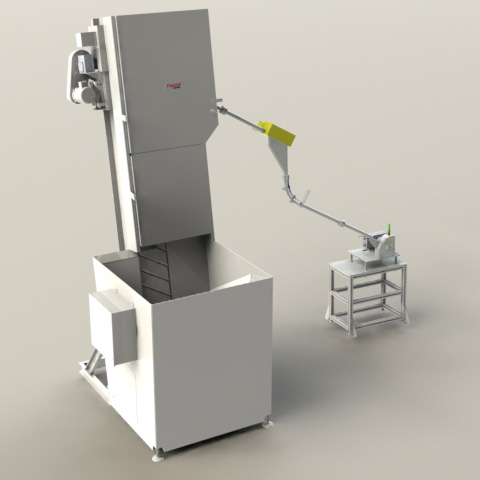

No spindles or fixtures are necessary to secure the part during the process. Instead, two rotary grinding wheels control the parts as they pass through the machine. Automating the feeding step further optimizes an already efficient process, enabling long-duration, unmanned operation.

From the beginning, Feedall Automation has worked with machine tool manufacturers to implement ways to streamline their centerless grinding operations. In centerless grinding, Cincinnati Milacron (now simply Milacron) was once the gold standard for producing outer diameter/cylindrical grinders.

Decades ago, Feedall worked hand-in-hand with Cincinnati Milacron to design and develop automation solutions to serve centerless grinders. That experience, which goes back 75 years, has led to finely tuned, proven tools dedicated to maximizing production for centerless grinding workstations.

Below you can explore the different solutions we provide that specifically address centerless grinding—but also can be implemented for many other industrial applications. Take a look at many of these units closer in our Video Library. Our automation equipment resources provide deeper information about all things related to automation. If you need to speak to our experts for further details, please reach out at any time.