End-of-Arm Tooling

EOAT

Tooling designed by the experts in part handling

The best vision solution on the market cannot compensate for poor tool design. For every part-handling application, we put the same care and attention to detail into our end-of-arm tool design as we do into the tooling on our feeders. Our team of experts in part handling will work with your team to design, test, and implement a tool that makes the most sense for your process, including:

- High part mix tooling sets

- Multi-pick processes

- Multi-stage part extraction

- Design for 3D bin picking

EOAT: Turning Robots into Productive Manufacturing Assets

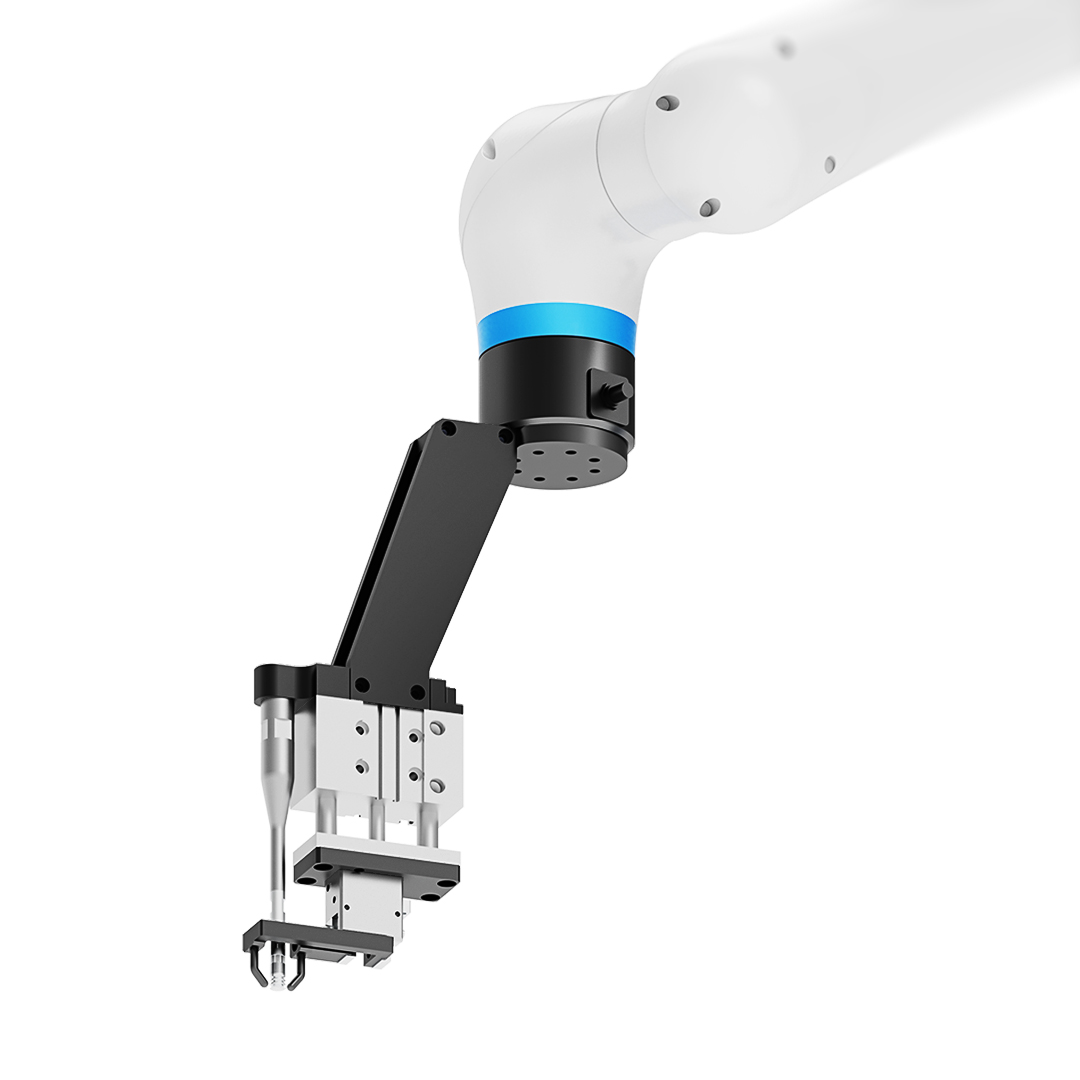

Industrial robots are reshaping modern manufacturing—but a robot arm alone doesn’t create value. The real work happens at the end of the arm. Robotic end effectors, also known as End-of-Arm Tooling (EOAT), are what allow robots to grip, move, assemble, inspect, and process parts reliably and efficiently.

At Feedall, EOAT is not an afterthought—it’s a core part of every feeding solution we deliver. By engineering the right EOAT from the start, we help manufacturers achieve faster cycles, higher uptime, and consistent performance on the factory floor.

Why the Right EOAT Makes All the Difference

No two automation applications are the same. Part geometry, weight, surface finish, orientation, and production variability all impact how reliably a robot can pick and place parts. A poorly designed EOAT can limit throughput, increase downtime, and drive up scrap—no matter how advanced the robot itself may be.

Feedall’s advantage is our deep expertise in part evaluation. Because we analyze parts as our core competency, we design EOAT solutions that are purpose-built for your application—maximizing reliability, repeatability, and return on investment.

With a properly engineered EOAT, manufacturers gain:

Faster cycle times and increased throughput

Consistent, repeatable part handling

Reduced scrap, rework, and unplanned downtime

Improved operator safety and ergonomics

Greater flexibility for future product changeovers

EOAT Solutions Designed for Real-World Production

Robotic Grippers

Grippers are the most common EOAT solution and are ideal for material handling, assembly, palletizing, and machine tending. Feedall integrates pneumatic, electric, and servo-driven grippers in parallel, angular, three-finger, and adaptive designs—ensuring secure part control and dependable performance across a wide range of applications.

Vacuum End Effectors

Vacuum EOAT uses suction cups or foam tooling to handle flat, lightweight, or porous parts. These systems are especially effective in packaging, palletizing, sheet handling, and logistics operations where speed, flexibility, and gentle handling are critical.

Custom End-of-Arm Tooling

Off-the-shelf tooling doesn’t always solve real production challenges. That’s why Feedall specializes in custom EOAT solutions. We design and build end-of-arm tooling to accommodate complex geometries, part variation, tight tolerances, and multi-function requirements—delivering reliable performance where standard tooling falls short.

Built to Perform. Designed to Deliver Results.

When EOAT is engineered correctly, robots become powerful, dependable production tools. Feedall’s integrated approach to part feeding and end-of-arm tooling ensures your automation system performs as intended—today and as your production needs evolve.

Looking to improve pick reliability, reduce downtime, or increase throughput? Feedall’s EOAT expertise can help turn your robotic system into a competitive advantage.