Feedall Flex

1018

Feed More Parts with Medium Flex Feeders

As the medium flex feeder option in our Flex series, the 1018 offers a larger vibratory recirculation table area while carving out its niche as the new standard in flexible feeders. The larger footprint opens up more versatility in the size of parts being fed into vision-guided robot applications all while bringing the same list of benefits:

- No expensive 3D robot guided vision required

- No programming required

- Eliminates manual feeding while allowing fast product changeovers

- Smooth and quiet part handling

- Superior part separation and manipulation for robot pick efficiency

Overview

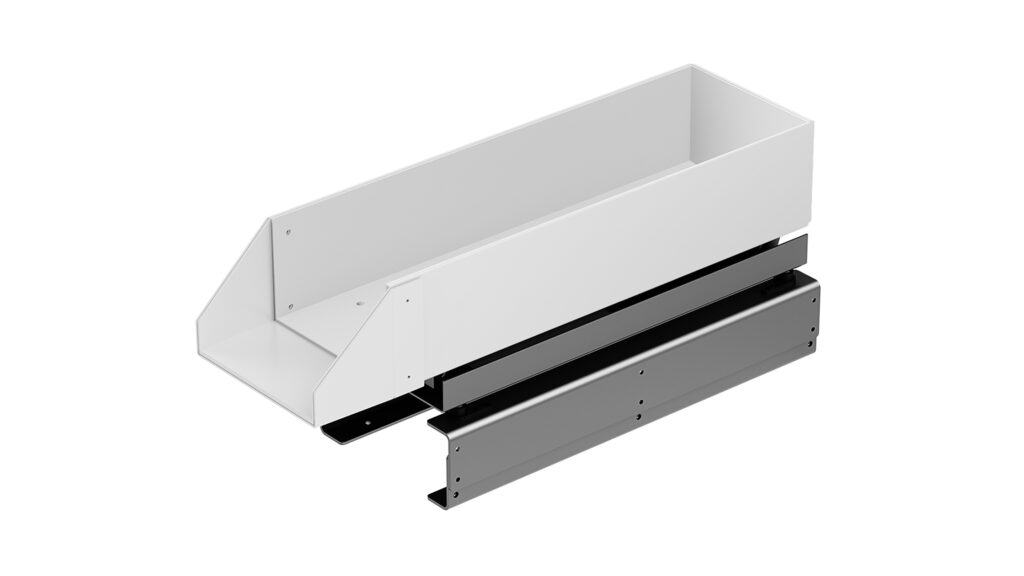

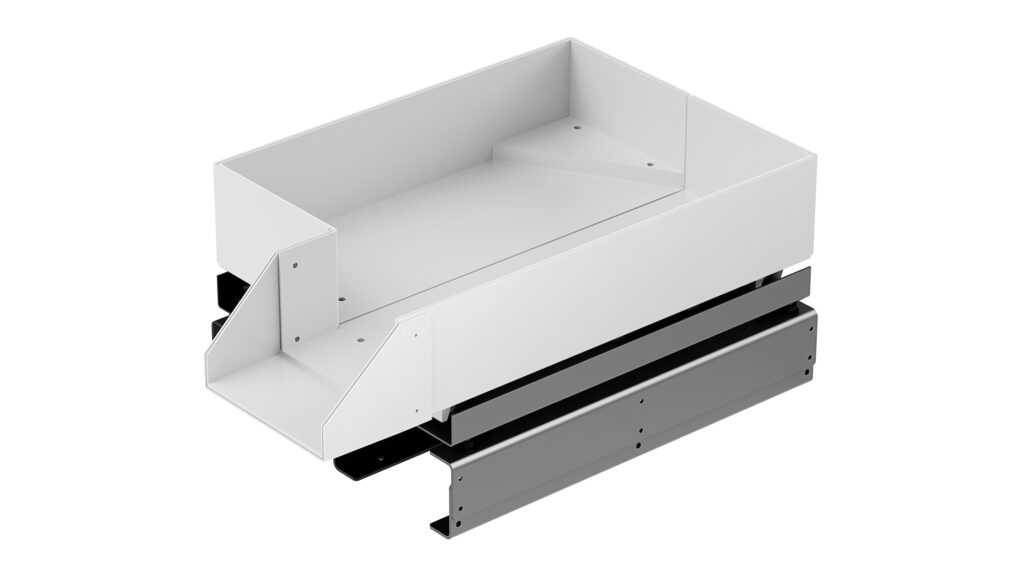

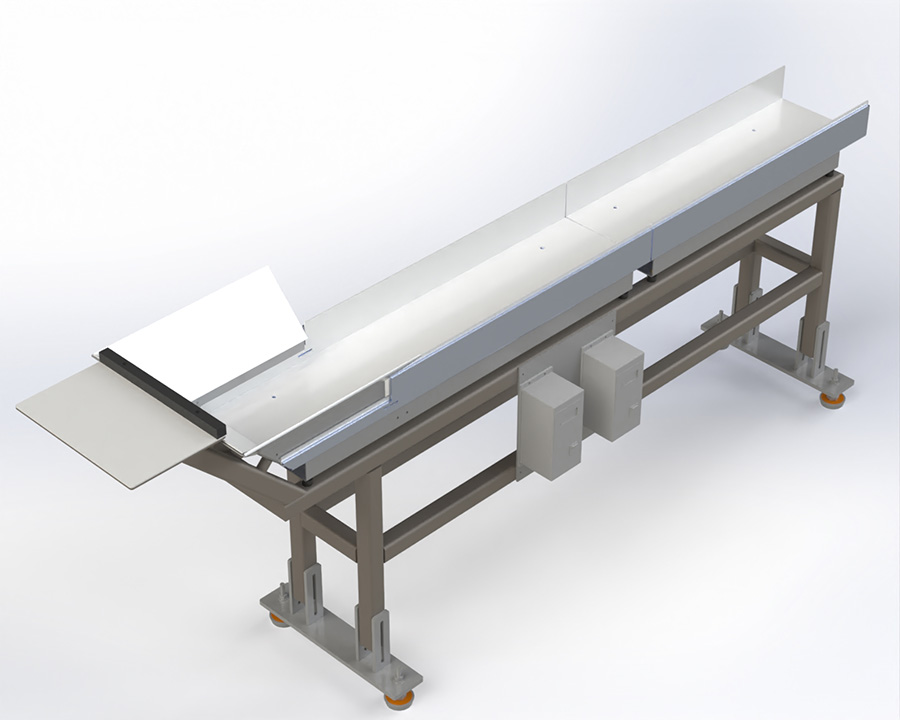

The Feedall Flex 1018 is our medium flex feeder with a base recirculating area of 10 inches by 18 inches and designated picking area. As parts move across the zone, the associated vision system identifies a ready part and coordinates the information to the robot element of the cell to pick the part. The seamless integration of Feedall’s flex feeders and their ability to navigate easily between different types and varieties of parts enhances your efficiency with already instituted robotic automation systems.

With an integrated hopper capable of handling more than 50 pounds of parts, the Feedall Flex 1018 has easy-to-navigate custom controls and can be running parts just seconds after initial setup. This model can be integrated as a table-top unit, or on a pedestal-style base to extend the pick area close to the associated robot unit.

Like our entire Flex line, the 1018 has many available options to further optimize production. Consulting with our automation experts and engineering team can help you identify which provides the best fit for your specific application.

- Optional Airbox for separating tangle parts

- Optional backlight for the picking zone

- Option gentle part flipping fixtures

- In-line or perpendicular hopper placement

- Modified hopper size and capacity