Feedall Flex

3042

Tap Into Our Extra Large Flex Feeder for Superior Capacity

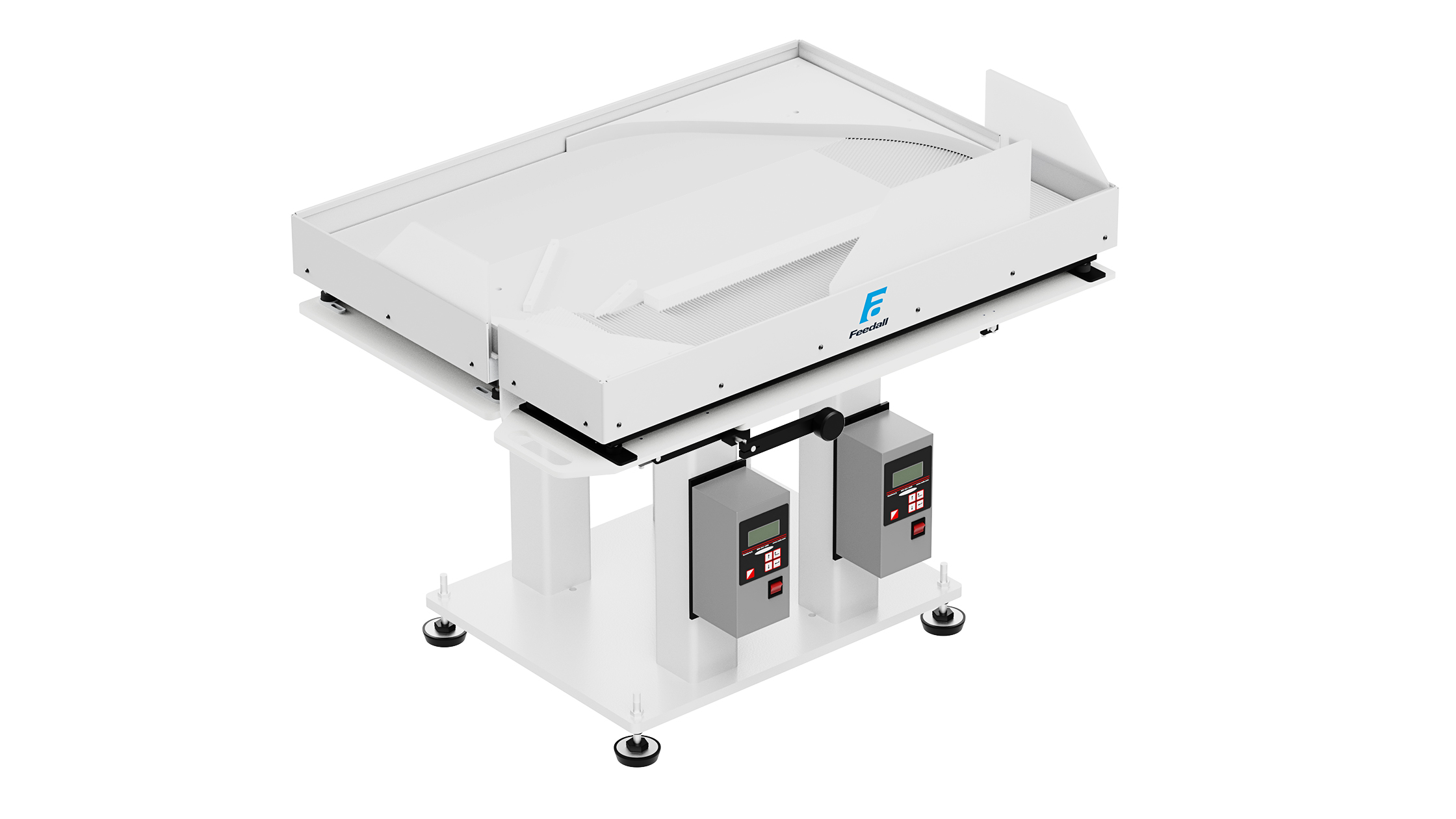

For the utmost flex feeding capacity and the capability to tackle the largest sizes of parts in a flexible feeding solution, the Feedall Flex 3042 provides the answer. While not ideal for every industrial automation application, this extra large flex feeder does offer the footprint to engineer unique and custom-driven solutions while delivering the high-end performance demanded in presenting parts for vision-guided robot applications.

- No expensive 3D robot guided vision required

- No programming required

- Eliminates manual feeding while allowing fast product changeovers

- Smooth and quiet part handling

- Superior part separation and manipulation

Overview

The Feedall Flex 3042 is equipped with the largest base recirculation table area among our standard models at 30 inches by 42 inches and operates like all of our flex feeders, including the inclusion of a designated picking area. Parts are circulated across the zone with the vision system singling out a part, communicating that information to the robot component, and then the robot picks the part.

Given its size, our extra-large flex feeder is capable of handling the largest part sizes of any entry in our Flex line. The integrated hopper can accommodate part loads in excess of the 100-pound benchmark of the Flex 1624. The custom controls facilitate streamlined integration and operation, and it can be installed as a standalone unit with its own pedestal-style stand or implemented as a table-top system.

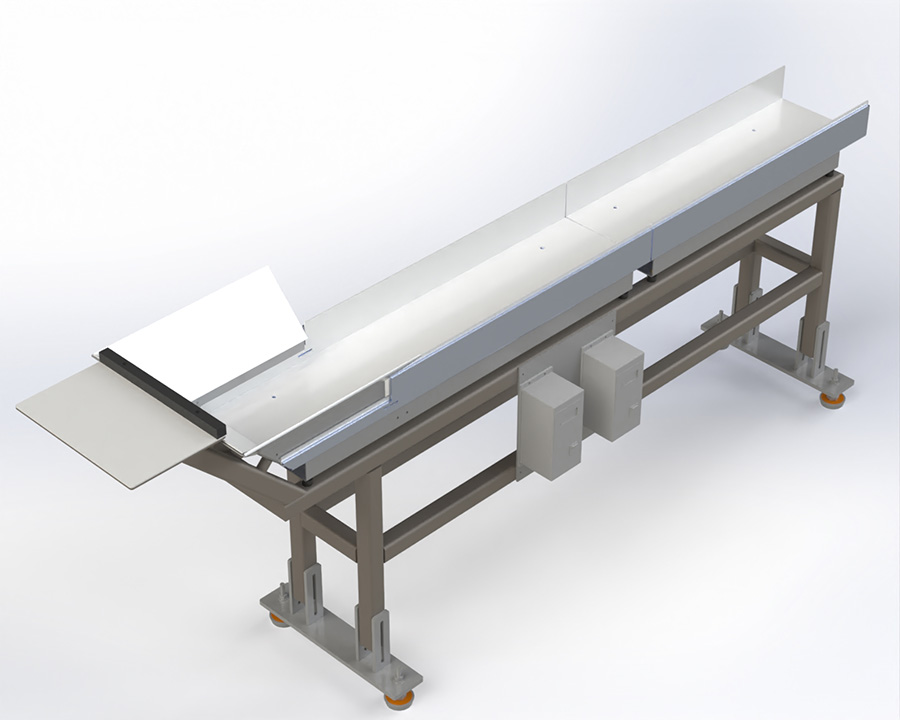

This extra-large flex feeder can be customized with a full assortment of optional features Twist Track, our gentle part-flipping addition, and multiple-lane functionality. Additional options are listed below. To get the most out of the Ridgeback 3042, connect with our automation experts and engineering team to identify the features essential to the success of your application..

- Optional Airbox for separating tangled parts

- Optional backlight for the picking zone

- Optional gentle part-flipping fixtures

- In-line, parallel, or perpendicular hopper placement

- Modified hopper size and capacity