Bulk Feeders For Rapid Part Presentation and More Substantial Parts

Feedall Automation specializes in premium bulk feeders with the highest quality standards; they are built to run 24 hours a day, 365 days a year. Large part feeders need to accommodate, move, and present parts with larger diameters and more length than their small part relatives. Our bulk feeders are designed to handle the additional load this requires while delivering the parts per minute performance needed to keep your robot cells and other production elements well fed.

Our Husky line provides a variety of bulk feeders with a diverse range of capabilities. These include random loaded elevator-style feeders that properly orient parts to dedicated billet feeders with heavier load capacity to bi-flow conveyors that rapidly deliver oriented parts to the next application, pick and place station, or other production stage. We create bulk feeders specific to the needs of your company and industry and our designs reflect more than 70 years of successful real-world applications—including vital elements like centerless grinding.

Explore our different Husky offerings below. You can check out many of our bulk feeders in our Video Library as well. Our free automation equipment resources section has a wealth of additional detailed information. If you need to speak to our automation experts, please reach out at any time.

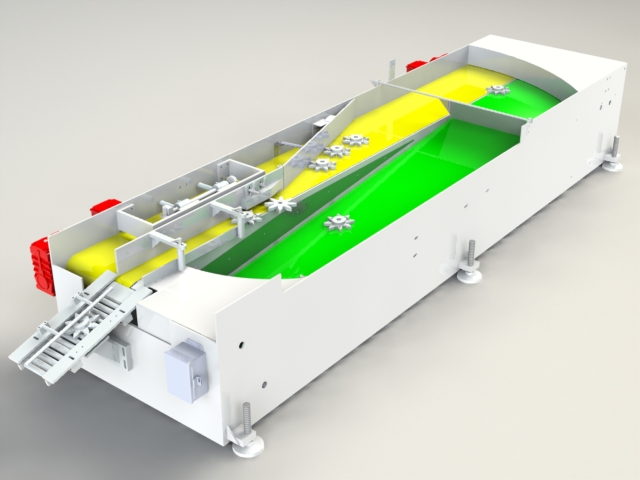

Husky

1500

Bi-flow conveyors offer unparalleled performance when speed and part orientation are critical.

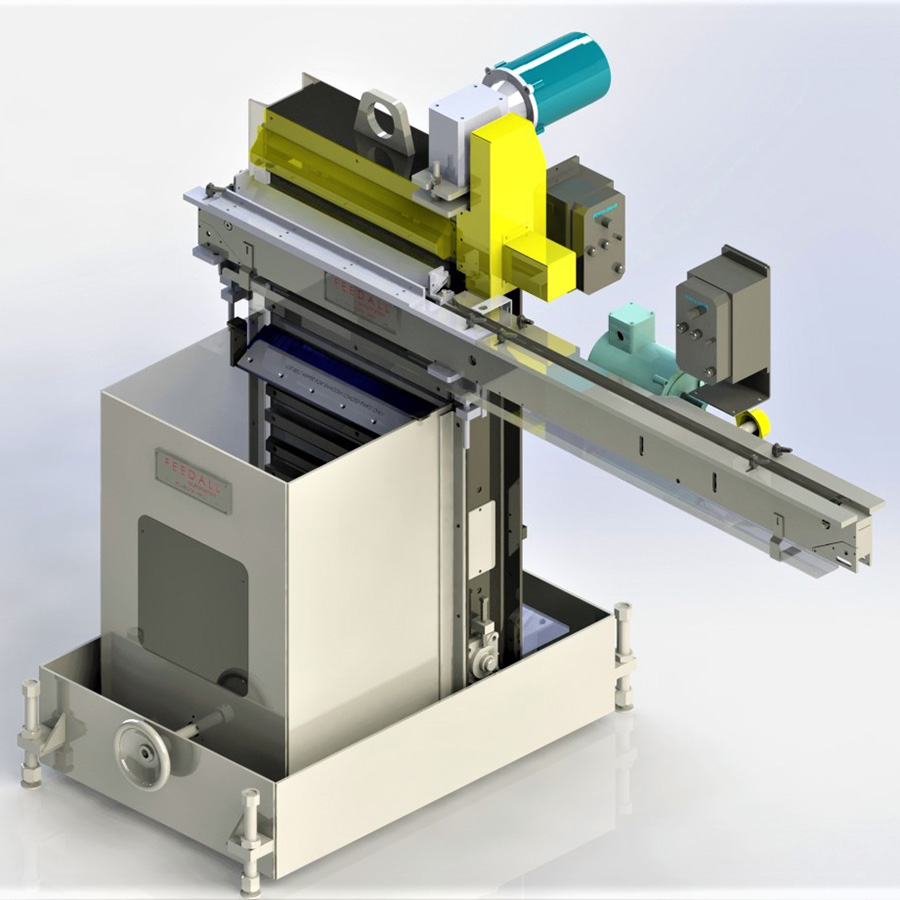

Husky

2000

Hopper fed—either bulk loaded or hand stacked—this billet parts feeder quickly processes cylindrical parts like cut bars, tubes, and shafts.

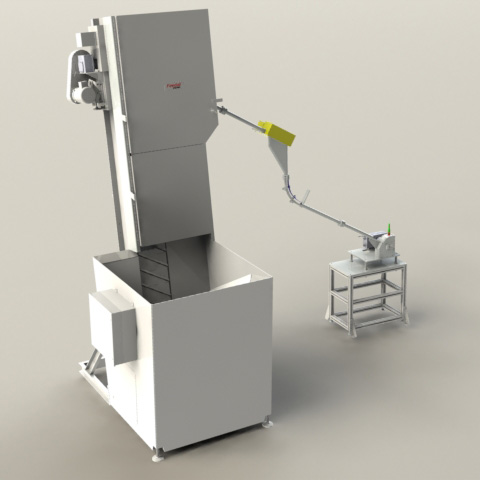

Husky

2400 / 2500

These random loaded bulk feeders use elevator mechanics to quickly orient and present parts for the next stage of production.

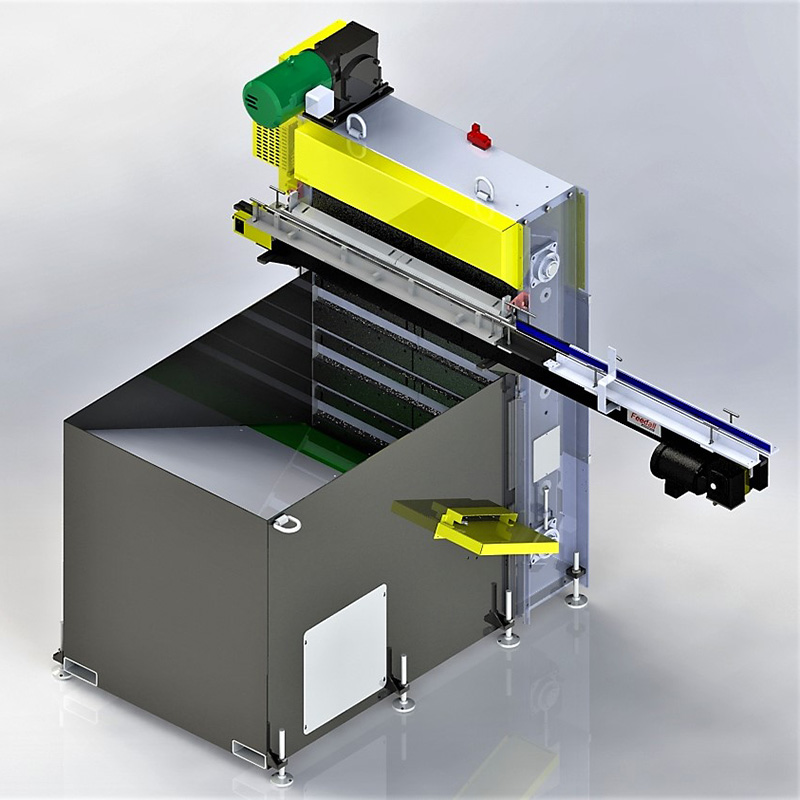

Husky

4800

Our heavy duty billet feeder handles cylindrical parts up to 6 inches in diameter and 30 inches in length.