Precision Part Conveyors

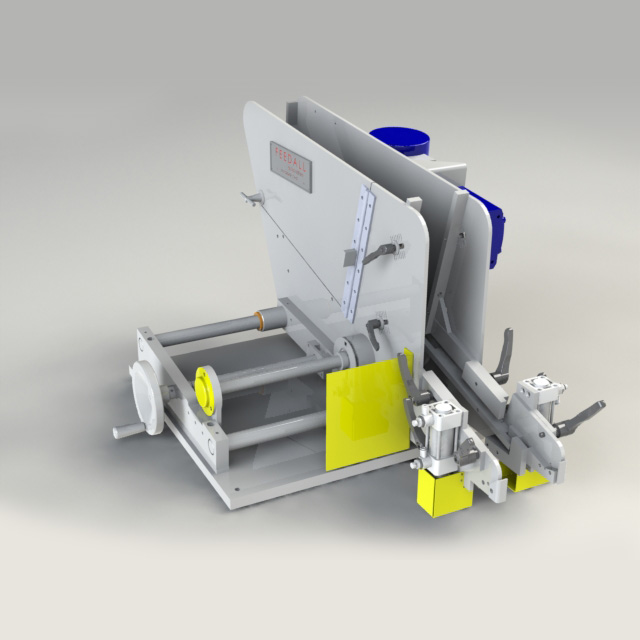

1650, 1680

Achieve Part Distribution Precision with Feedall’s Belt Conveyors

Feedall Automation’s line of Pointer belt conveyors provide entrance, intermediate and exit capabilities for a wide array of machine tools and processes, including delivering parts to robotic production cells. Special design considerations allow these conveyors to operate in harsh manufacturing environments, that may contain oily conditions, grinder swarf, chips, and the like. The versatility of the design of our belt conveyors allow them to integrate smoothly with all of our automation equipment and can be easily adjusted to use load ramps, hopper feeders, dumpers, and metering hoppers to add capacity.

Our Pointer belt conveyors also come with belting options.

Overview

The Pointer 1650 flat belt conveyor handles parts quickly and smoothly from one workstation to the next. They are often used in conjunction with our Retriever line of bar feeders to provide a complete automatic feeding system. These units typically feature conveyor lengths of 62 ½ inches to 72 inches, with a diameter range of ¼ inch to 2 inches.

Optional features include:

- Conveyor lengths from 36 to 144 inches

- Mechanical part cam off block with short discharge ramp

- Powered overhead driven wheel

- Floor stands and support bases

- Ball bushing mounts (floor stand and base)

- 2-inch wide silent chain or belt

- Custom designed applications

- Air operated side transfer devices

- Gap style conveyor for inline gauging

- Remote mounting of DC Controller custom designed to suit

The Pointer 1680 dual round belt conveyor is ideal for feeding, transferring cylindrical parts when precise lateral location of the part is critical. Capable of feeding many kinds of parts, these units come equipped with a gear-motor and variable frequency controller.

The 1680 uses a precision machined side plate, rather than an aluminum extrusion, for a more rigid structure for increased operational life. The biggest benefit of dual belt conveyors is that they allow coolant, lubricants and metal chips to escape back into the machine and not on to the floor. The low profile side rails allow it to fit into the tightest spaces.

Optional features include:

- CINCINNATI style mounting brackets for both entrance and exit end of grinder

- Custom designed direct mounting plates

- Floor support stands with optional linear bearings for wheel wear compensation

- Optional drip pans, side and top guides, and diverters

dual round belt conveyor is ideal for feeding, transferring cylindrical parts when precise lateral location of the part is critical. Capable of feeding many kinds of parts, these units come equipped with a gear-motor and variable frequency controller.

The 1680 uses a precision machined side plate, rather than an aluminum extrusion, for a more rigid structure for increased operational life. The biggest benefit of dual belt conveyors is that they allow coolant, lubricants and metal chips to escape back into the machine and not on to the floor. The low profile side rails allow it to fit into the tightest spaces.

Optional features include:

- CINCINNATI style mounting brackets for both entrance and exit end of grinder

- Custom designed direct mounting plates

Floor support stands with optional linear bearings for wheel wear compensation - Optional drip pans, side and top guides, and diverters