CASE STUDY

11060: PROJECT FEEDING SOCKET SHELLS INTO CNC TURNING CENTER

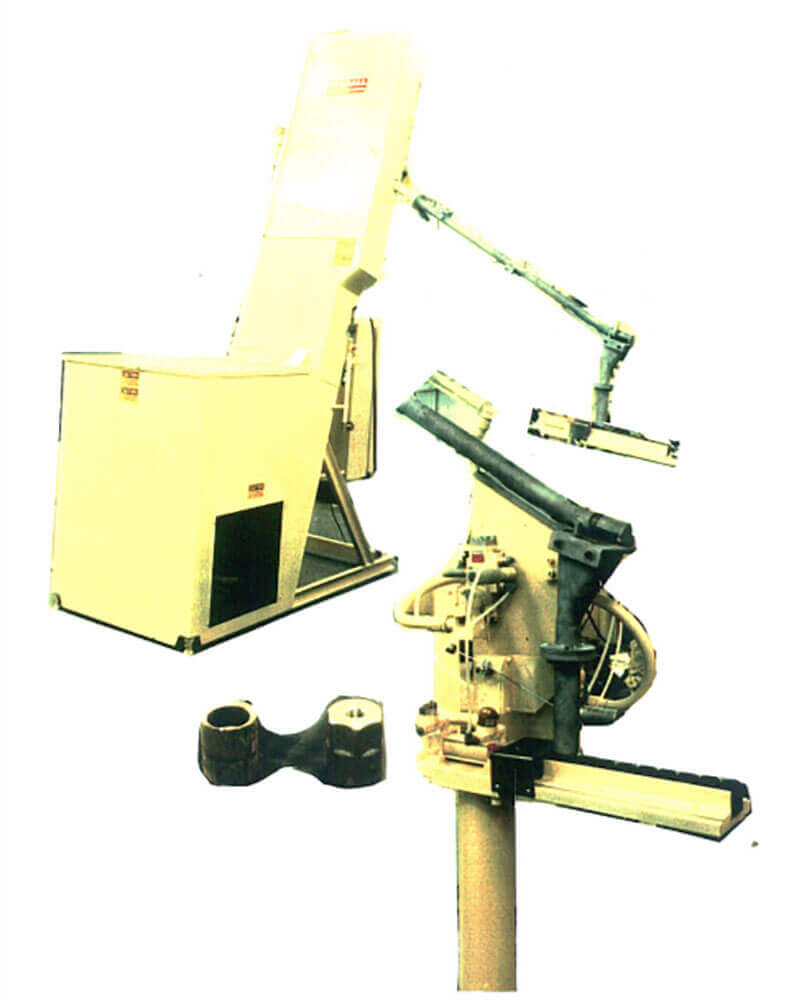

Feedall Model

Model 2400 D

APPLICATION

Feed from a random loaded floor mounted hopper, socket shells of various sizes. The sockets will first be oriented end to end then fed and oriented with the axis vertical and the hex head down into a vertical stack to a transfer device advancing the sockets horizontally DIA. to DIA. at a height of 42″ above the floor at a rate of 450 to 500 per hour.

7 1/2″ wide elevator belt, 15 CU. FT. Hopper.

DWG. P7707 R 3

WIDTH

7 1/2" wide elevator beltFEED RATE

450 to 500 per hour Menu

Menu