CASE STUDY

11275: PROJECT FEEDING FOOT & FOOT FOLLOWER INTO MULTI-SPINDLE CHUCKER

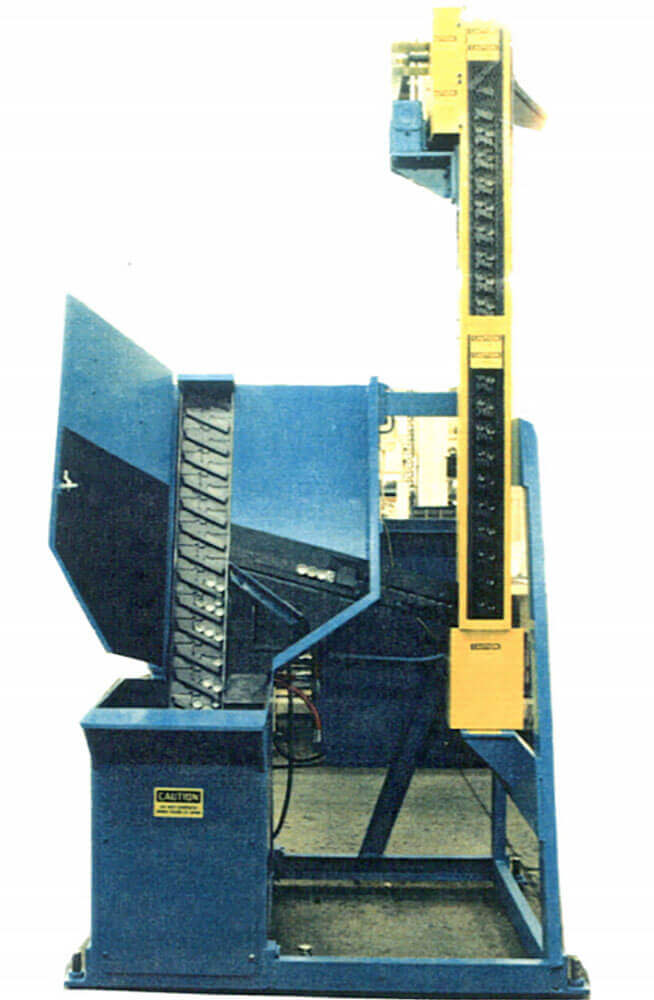

Feedall Model

Model 2400 C

APPLICATION

Feed from a random loaded floor mounted hopper hydraulic valve lifter caps. The caps are to be face select oriented and fed rolling in to an acme chucher load chute at 88″ above the floor at a rate of 20 to 30 parts per. min. Note: this is the second operation on the part in an acme, orientation was completed low close to the hopper, thus reducing part damage from part fall back, an auxiliary elevator was used to elevate pre-oriented parts to the discharge height of 88″.

6″ wide elevator belt, 2CU. FT. hopper.

DWG. P 7843

WIDTH

6" wide elevator beltFEED RATE

20 to 30 parts per minute Menu

Menu