CASE STUDY

16049: PROJECT FEEDING TORQUE CONVERTER IMPELLER HUBS INTO CENTERLESS GRINDER

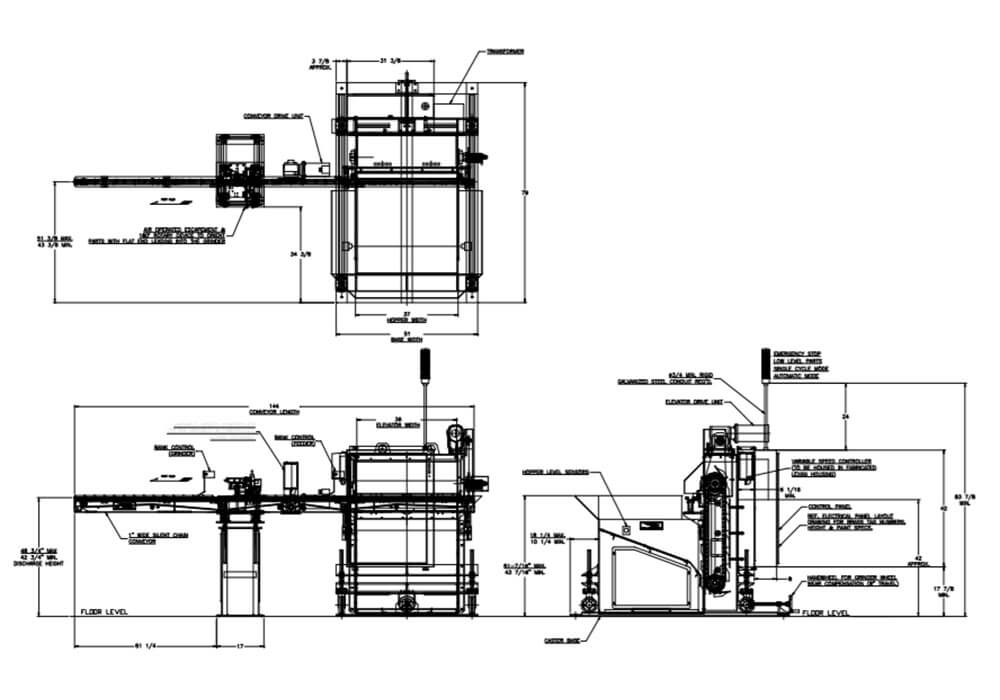

Feedall Model

Model 3600 Elevating Hopper Feeder w/1650-1SC-144 Cross-Feed Conveyor

APPLICATION

Feed from a random loaded, floor mounted hopper. The Torque Converter Impeller will be vertically elevated and deposited onto a crossfeed conveyor where they will be conveyed end to end to an orienting mechanism checking for flats on the parts. Once orientation has been established, the parts will be escaped one at a time to a 180° rotating device which will turn the part 180º with flat end leading (NOTE: Parts that are already in the correct orientation will not require rotation). The parts will then be fed in a continuous end-to-end stream to a centerless grinder.

WIDTH

36” Wide Elevating BeltDRIVE

1 HP/AC MotorPARTS FED (SIZE)

Torque Converter Impeller Hubs (1.50”Ø x 2.15”-3.56” Lg.)FEED RATE

1,000-1,200 Parts/Hour Menu

Menu