CASE STUDY

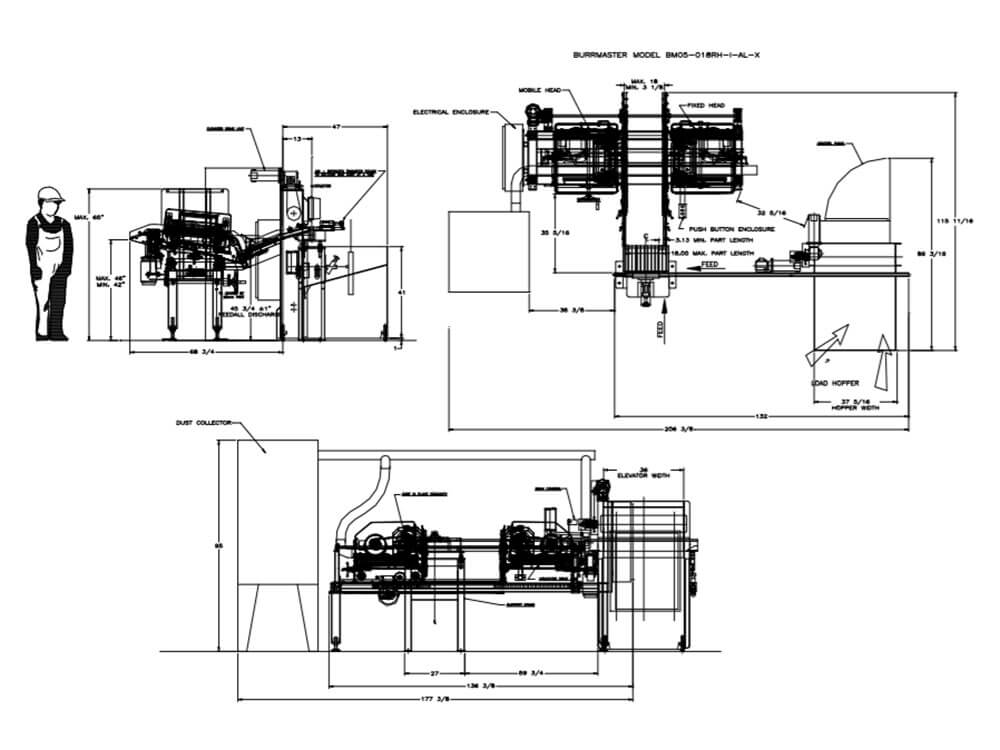

16737: PROJECT FEEDING ALUMINUM TUBES INTO DEBURRING MACHINE

Feedall Model

Model 3600 Elevating Hopper Feeder w/1650-1SC-132 Cross-Feed Conveyor

APPLICATION

Feed from a random loaded, floor mounted hopper. Aluminum Tubes will be elevated out of the hopper via a cleated belt and deposited onto a front-end mounted, cross feed conveyor. The conveyor will translate the tubes in a continuous, end-to-end, stream into a transfer device. The transfer device will transfer the parts one at a time rolling, diameter-to-diameter into BurrMaster load magazine.

WIDTH

36” Wide Elevating BeltDRIVE

1/2 HP/AC MotorPARTS FED (SIZE)

Aluminum Tubes (0.50”-0.75”Ø x 3.20”-16.86” Lg.)FEED RATE

60 Parts/Minute Menu

Menu