CASE STUDY

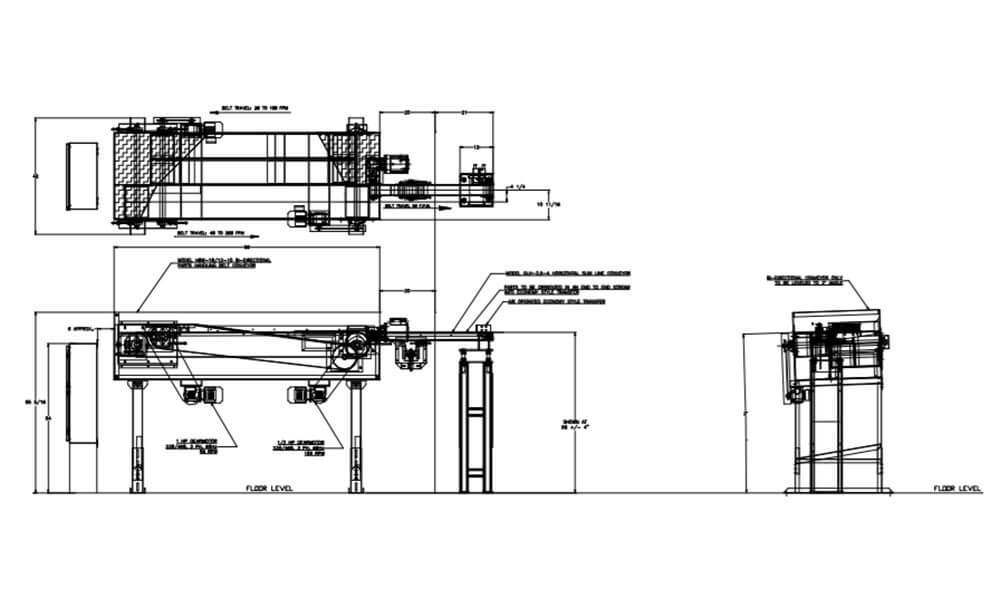

17616: PROJECT FEEDING STEEL TUBES INTO END FINISHER

Feedall Model

Model 1500 Bi-Directional Orienting Conveyor w/GLH-3.5-4 Exit Conveyor

APPLICATION

Feed from a random loaded floor mounted hopper. The parts will meter from a customer

supplied elevator on demand and spilled randomly onto a bi-directional feed conveyor. The

parts will merge from the infeed conveyor portion onto the orienting conveyor lane and exit in

a continuous stream to an automatic air operated economy style transfer device.

Then the parts will be loaded in a diameter-to-diameter stream into an existing load chute.

WIDTH

18” Return Lane and a 12” Orienting LaneDRIVE

1-1/2 HP/AC MotorPARTS FED (SIZE)

Steel Tubes (0.500”-2.375”Ø x 2.000”-8.000” Lg.)FEED RATE

20 parts/minute Menu

Menu