CASE STUDY

17710-17711: PROJECT FEEDING PIPE FITTINGS INTO ROBOT LOADED MACHINING CENTER

Feedall Model

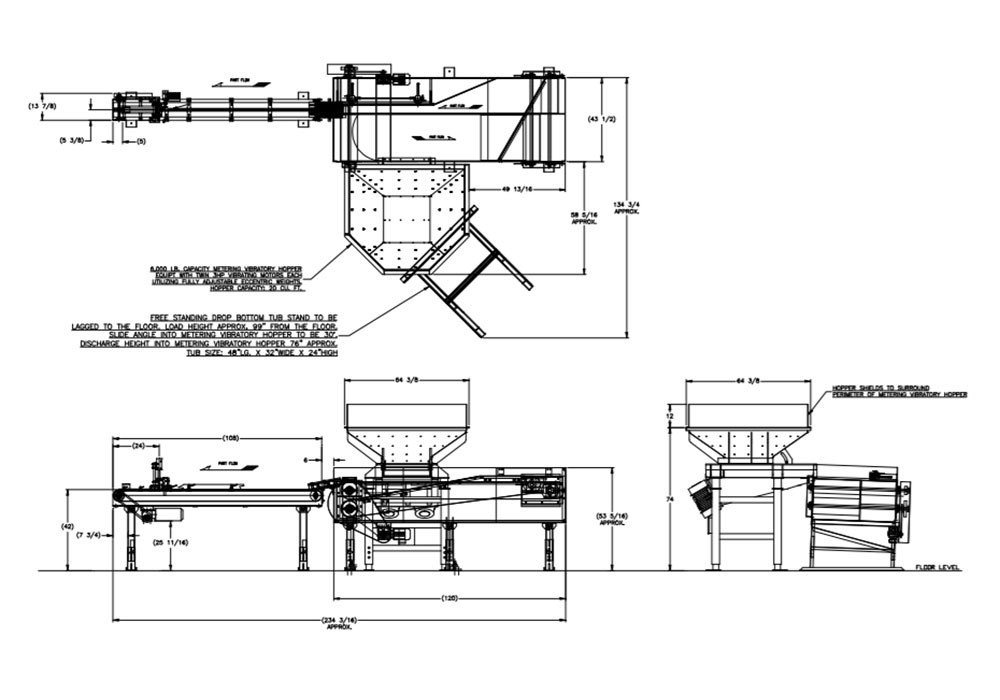

Model 1500 Bi-Directional Orienting Conveyor w/6,000# Vibratory Metering Hopper & Tub Stand

APPLICATION

Feed parts from a drop bottom tub stand. The parts will be spilled randomly onto a bidirectional feed conveyor. The parts will merge from the in-feed conveyor portion onto the

discharge conveyor. The parts will be escaped one at a time onto a customer supplied pick-n place unit.

WIDTH

24” Return Lane and 18” Orienting LaneDRIVE

1-1/2 HP/AC MotorPARTS FED (SIZE)

Pipe Fitting ForgingsFEED RATE

15 Parts/Minute Menu

Menu