CASE STUDY

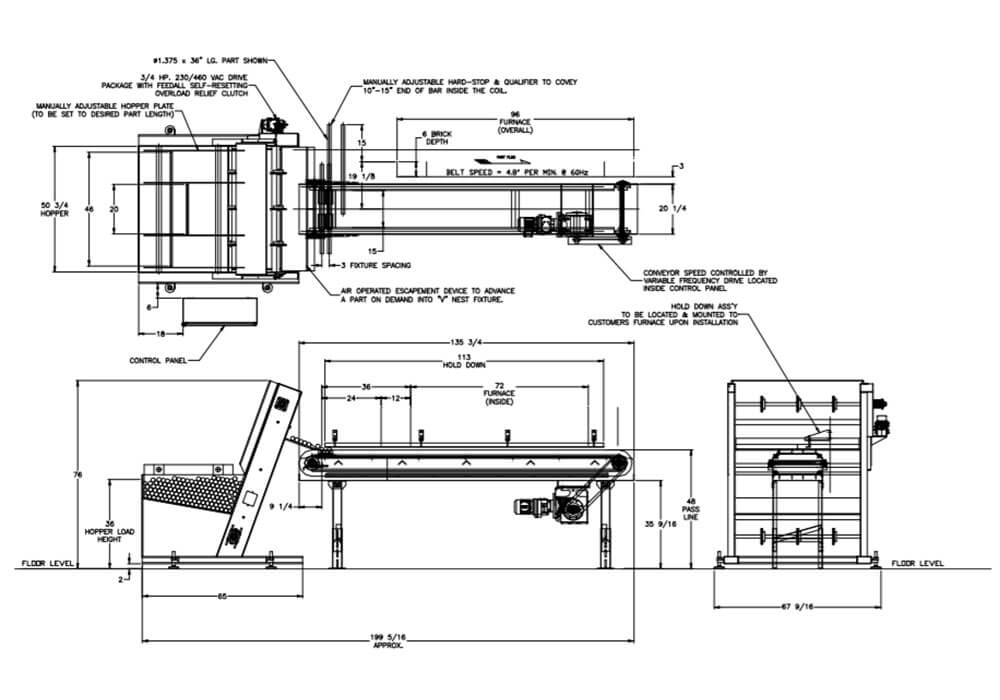

17836-17837: PROJECT FEEDING STEEL BILLETS INTO FURNACE HEATER

Feedall Model

Model 2250 Elevating Hopper Feeder w/O6W-02-11 Discharge Conveyor

APPLICATION

Feed from a manually loaded, floor mounted hopper, Sheared Steel Billets. The Billets will be elevated from the hopper via a cleated belt and carried over the top of the elevator and deposited onto a rear mounted, accumulation ramp in a continuous, diameter-to-diameter stream. An air-operated escapement device will load one part at a time onto Discharge Conveyor equipped with an air-operated pusher device to qualify Billet length entering Channel Furnace Heater.

WIDTH

50” Wide Elevating BeltDRIVE

3/4 HP/AC Motor w/Variable Speed Drive and Overload Relief Clutch1/3 HP/AC Motor w/Variable Frequency Controller

PARTS FED (SIZE)

Sheared Steel Billets (0.88”-1.75”Ø x 20”-46” Lg.)FEED RATE

1 Part/40 Seconds Menu

Menu