Vibratory Escapement Feeders

612X, 1018X, 1624X, 3042X

Vibration Feeders Deliver Intelligent Design & Precision

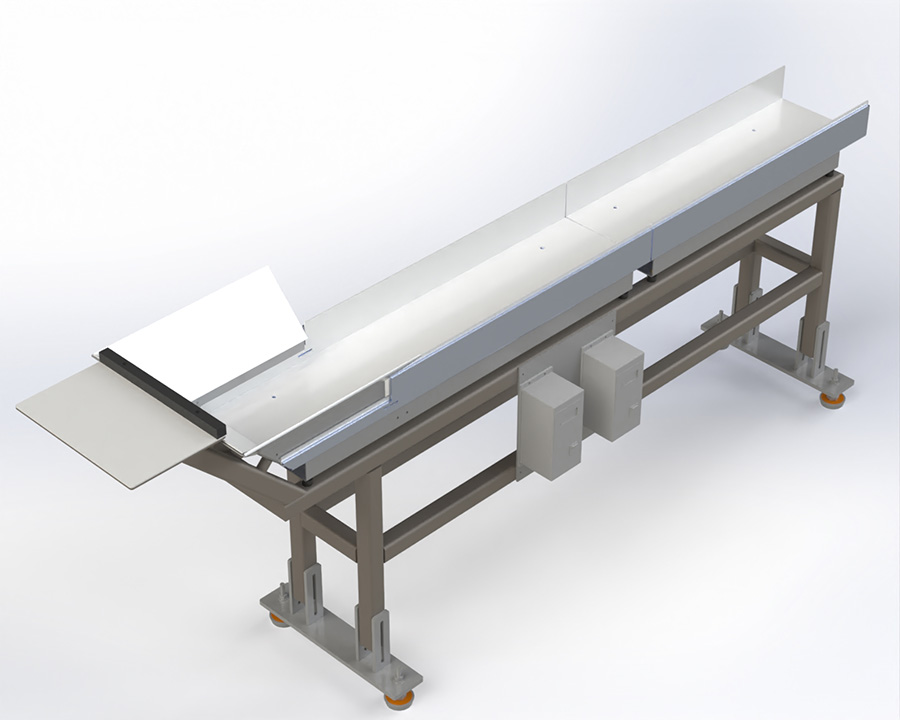

Feedall Automation’s line of Aussie vibration feeders uses a table that vibrates to move parts from a mass of bulk parts toward an exit point. Through the use of weartrack design and vibration patterns, parts are oriented and singulated for release through the exit to provide a continuous feed of parts. Focused on smaller parts, linear vibratory feeders can handle a wide variety of shapes and materials. They provide a cost-effective piece of automation equipment commonly used in many applications, such as feeding parts to robotic assembly cells, or packaging equipment.

Overview

Our Aussie vibration feeders provide a strong alternative to vibratory bowl feeders, with the flatbed design providing a more gentle, non-marring approach to moving and orienting parts. In addition to protecting parts better, they also produce less noise and have a smaller power profile in comparison.

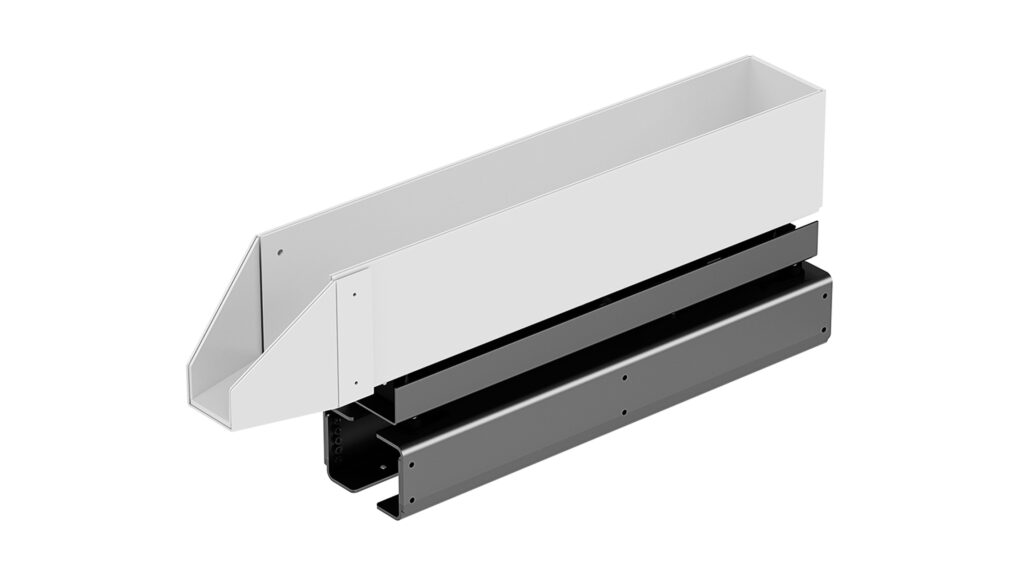

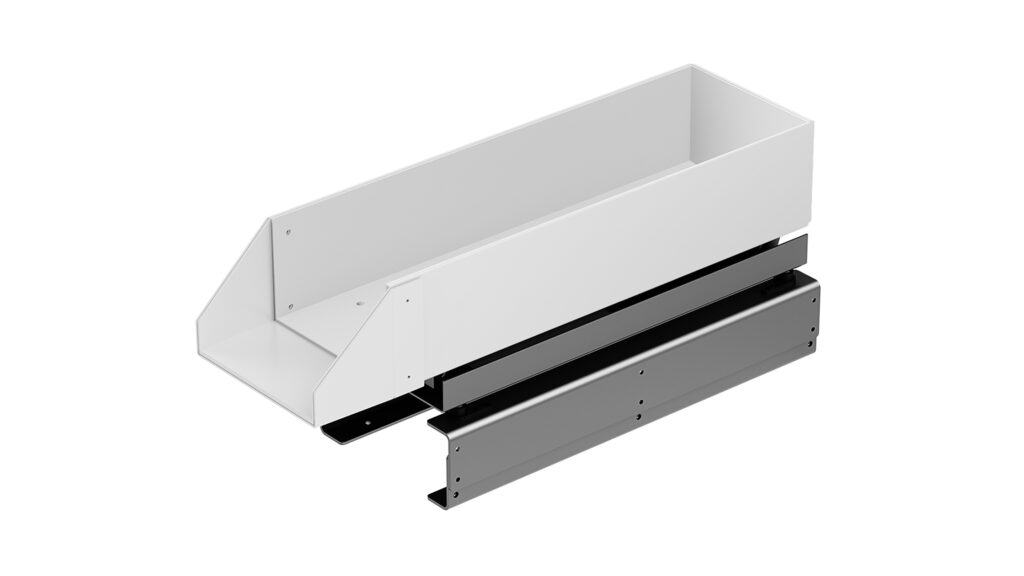

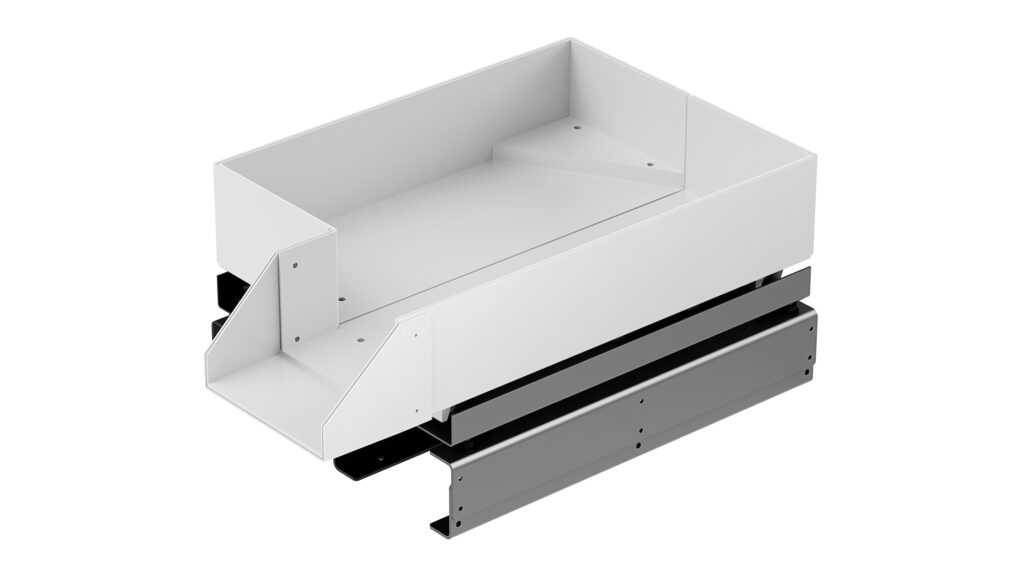

Due to these inherent strengths, our linear vibratory feeders are capable of handling parts of many shapes including disks, wheels and circle-shaped parts to small pins and tubes to parts with more complex geometries. An assortment of custom filtering add-ons and escapements are also available, adding improved part orientation capabilities to better suit robot product cells down the line without the need for a 2D or 3D camera system.

Our Aussie vibration feeders come in five model numbers, each related to the footprint they require on a factory floor:

- 612X — Our smallest vibration feeder (6 inches wide by 12 inches long)

- 1018X — Our medium-sized model

- 1624X — The large version of our linear vibratory feeder

- 3042X — Our largest footprint vibration feeder

- 9000 — Have a very specific requirement? Get a custom size model