Industrial Part Feeding Systems: Types, Applications, and Automation Strategy

Industrial automation is only as reliable as the way parts are delivered to the process.

Even the most advanced robotics, vision systems, and assembly equipment cannot perform at their best if parts arrive inconsistently — or if operators must manually load components to keep production moving.

That is why part feeding systems are one of the most important foundations of modern manufacturing. Whether you’re running a high-speed dedicated assembly line or building a flexible robotic cell, the right feeding strategy directly impacts:

Throughput

Uptime

Labor costs

Changeover time

Long-term ROI

In this guide, we’ll break down what part feeding systems are, the most common feeder types, and how to determine the best solution for your automation environment.

What Are Part Feeding Systems?

Part feeding systems are automation solutions designed to take parts from bulk supply and deliver them in a consistent, repeatable manner to downstream equipment.

A well-designed feeding system typically performs three critical functions:

Supplies parts continuously (preventing machine starvation)

Separates parts from bulk supply (reducing tangling and jams)

Presents parts in a usable orientation (for assembly, inspection, or robotic picking)

Without stable feeding, even the most advanced automation system becomes unreliable.

Why Part Feeding Systems Matter in Automation

In real-world production environments, feeding is often where automation projects succeed or fail.

1. Throughput

If parts are not delivered fast enough, robots and machines sit idle. Feeding directly determines production speed.

2. Uptime

Feeding-related jams and misfeeds are among the most common causes of downtime in automated systems.

3. Labor Reduction

Manual loading introduces variability and ongoing labor cost. Automated part feeding systems eliminate this dependency.

4. Quality Control

Inconsistent part orientation increases the risk of mispicks, improper assembly, and downstream defects.

A properly engineered part feeding system stabilizes the entire automation cell.

The Most Common Types of Industrial Part Feeding Systems

There is no single “best” feeder — only the right feeder for your application.

1. Vibratory Bowl Feeders

Vibratory bowl feeders use controlled vibration to move parts along a spiral track. Tooling along the track orients parts into a repeatable position before discharge.

Best for:

High-volume production

Single part type

Stable, long production runs

Small to medium components

Strengths:

High feed rates

Proven reliability

Excellent orientation precision

Limitations:

Custom tooling required

Slower changeovers

Not ideal for high-mix production

2. Flexible Feeding Systems

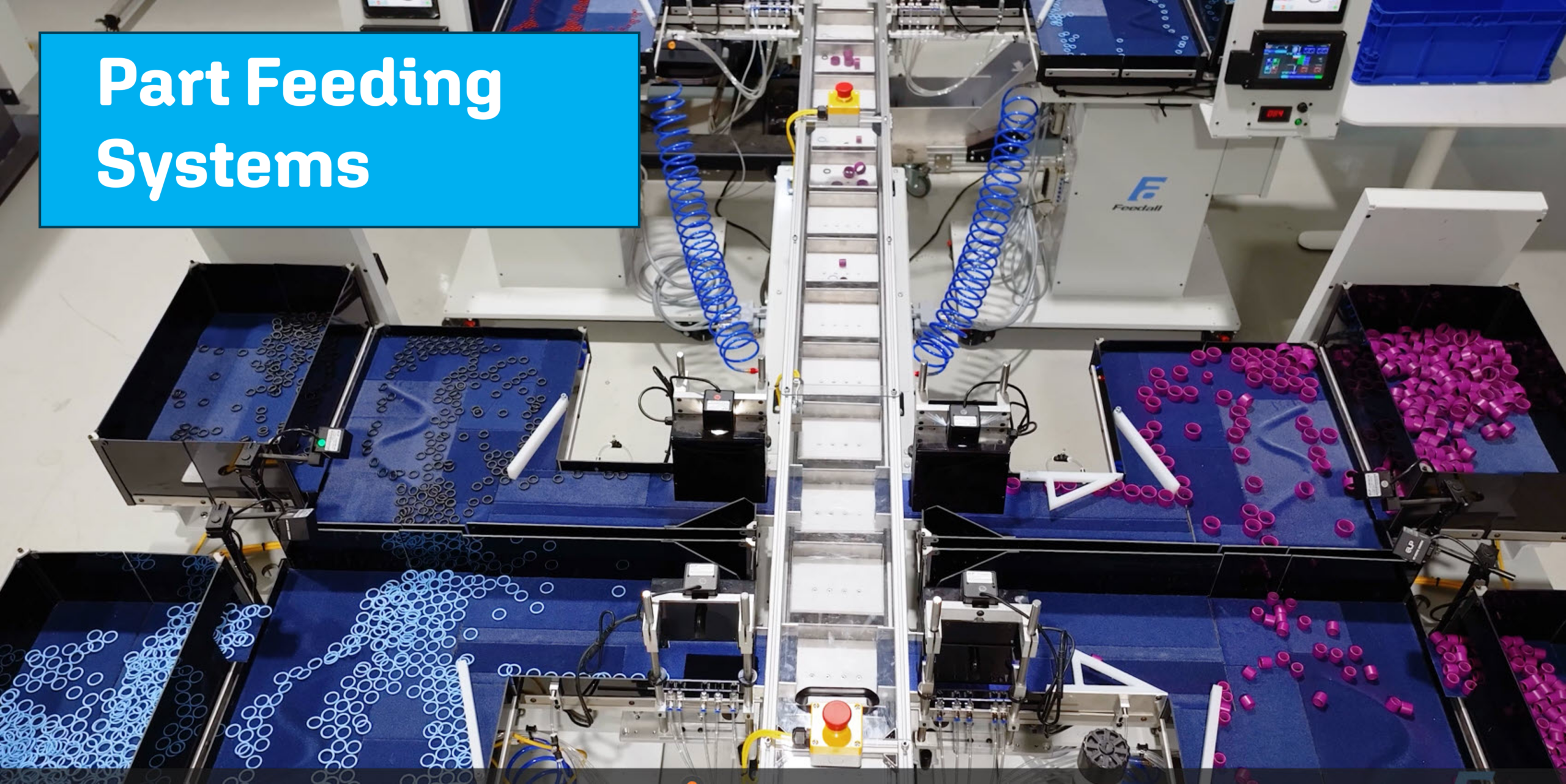

Flexible feeding systems (also called flex feeding) use vibration, vision systems, and robotics to identify and pick parts without hard tooling.

Instead of mechanically orienting parts, they:

Spread parts across a surface

Use cameras to locate pickable components

Guide a robot for pick-and-place

Best for:

Multiple part types

High-mix manufacturing

Robotic automation cells

Frequent changeovers

Flexible feeding has become the preferred strategy for manufacturers seeking long-term adaptability.

3. Centrifugal Feeders

Centrifugal feeders use spinning discs to orient parts at high speed with reduced noise.

Best for:

Lightweight components

High-speed orientation

Noise-sensitive environments

4. Vibratory Conveyors and Linear Feeders

These systems transfer parts between stages and provide buffering.

They are commonly used:

Between bowl feeders and assembly stations

To maintain spacing

For controlled part movement

5. Bulk Feeders and Hoppers

Bulk feeding systems supply large volumes of parts to orientation equipment.

They:

Reduce manual refilling

Maintain consistent supply

Improve line stability

Bulk feeders are often paired with bowl feeders or flexible feeding systems.

How to Choose the Right Part Feeding System

Selecting the right system requires evaluating both part characteristics and production strategy.

Part Geometry

Does the part nest or tangle?

Is orientation critical?

Is the surface reflective or delicate?

Is it symmetrical?

Production Volume

High-volume, single SKU → Bowl feeding often wins.

Multi-SKU, changing parts → Flexible feeding is usually better.

Changeover Frequency

Frequent changeovers make hard tooling less attractive.

Robotics Integration

If robotics are central to the automation cell, flexible feeding systems often integrate more seamlessly.

Long-Term Scalability

The lowest upfront cost is not always the best long-term investment. Consider future product evolution.

Modern Strategy: Hybrid Feeding Systems

Many manufacturers now combine technologies:

Bowl feeders for dedicated, high-volume parts

Flexible feeders for evolving SKUs

Bulk feeders for stable supply

This hybrid strategy balances throughput and flexibility.

Common Applications of Part Feeding Systems

Part feeding systems are used across nearly every industrial sector:

Automotive manufacturing

Electronics assembly

Medical device production

Consumer products

Packaging systems

Aerospace components

Any operation requiring consistent, repeatable part presentation can benefit from optimized feeding.

Frequently Asked Questions

What is the purpose of a part feeding system?

A part feeding system supplies, separates, and presents parts consistently so automated equipment can operate efficiently without manual loading.

What is the difference between a bowl feeder and a flexible feeder?

A bowl feeder uses mechanical tooling to orient one part type at high speed.

A flexible feeder uses vibration and vision to handle multiple part types with faster changeovers.

Can part feeding systems integrate with robotics?

Yes. Modern part feeding systems are often designed specifically for robotic automation, especially flexible feeding solutions.

Final Thoughts: Automation Starts with Feeding

Industrial automation does not start with robots — it starts with feeding.

A properly engineered part feeding system improves:

Throughput

Uptime

Labor efficiency

Product quality

Long-term ROI

Whether you require vibratory feeding, flexible feeding, or a hybrid solution, designing the right feeding strategy is the foundation of reliable automation.

If you’re planning an automation project, Feedall can help you determine the optimal feeding system for your application and production goals.