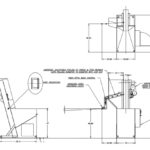

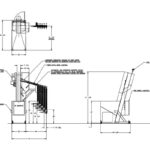

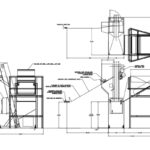

Random Loaded Feeder (Small Parts)

Model 2400

“Random”-Loaded-Hoppers-for-Centerless-Grinders-2.pdf

Small Parts Random Loaded orienting part Feeder Models

Random Loaded Feeders – 2400-2700

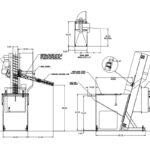

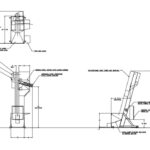

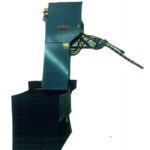

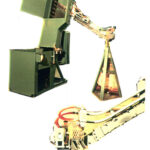

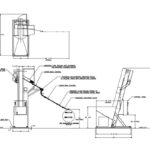

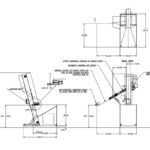

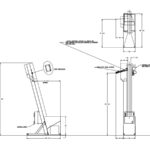

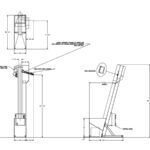

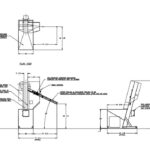

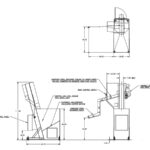

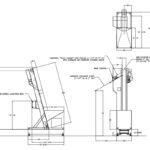

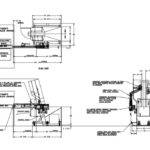

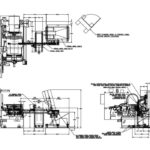

Feedall Orienting Hopper Feeders — Designed specifically to automatically feed random loaded sliding, rolling headed or hanging parts with diameter ranges within a 2:1 ratio. Parts are elevated and gravity fed into chutes with various orienting devices designed to provide a continuous flow of product. These feeders may be used to feed all types of grinders, presses, machining equipment, and specialty machines, including forging equipment.

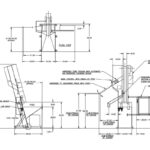

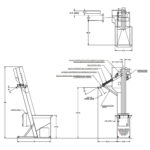

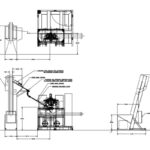

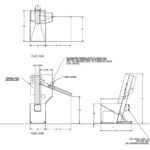

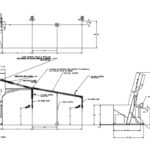

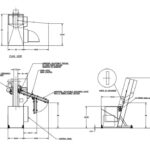

Model 2400 Hopper Feeders – The Standard light-duty machine is a Model 2400-C, with hopper capacity of 6 cubic feet. It has a 6″ wide elevating belt and occupies floor space of 30″ by 60″. Typical parts handled are ball studs, rods, inner and outer bearing races, trunnions and bushings. For Larger work or higher feeding rates, the Model 2400-D has a 7 1/2″ wide elevating belt.

Feedall standard features which provide maximum productivity:

- Proper part delivery – Parts are oriented and placed in a chute, with right or left hand takeoff, or two track delivery

- “Custom” elevators – Cleat height and spacing on elevators are designed to size of

parts being fed. Only minimum maintenance is required for moving parts. Chutes, wear strips, cleats and tooling are hardened for extra long service. - Custom designed accessories – Automatic bank controls, air operating devices, diverters, timing controls and other special equipment may be added with new tooling designs

- Tooling plate – This feature controls the rate at which parts fall into the hopper. For added

protection, it may be easily equipped with polyurethane-lined baffles. - Adjustable elevation – Height of the elevator tower may be varied to suit the application. Extra high discharge heights are available.

- Speed Control – Feed rate is determined by the speed of the elevating conveyor, which has a self-contained mechanical variable speed drive or infinite speed D.C. drive optional. Handweel adjustment is easily accessible.

View 3D Model

Best viewed on desktop

Menu

Menu