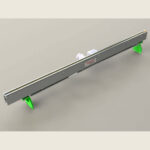

Precision Conveyors (Dual Round Belt)

Model 1680

Precision Conveyor Models

Model 1680 Dual Round Belt Precision Conveyors are ideal for feeding, transferring, and removing cylindrical parts from machinery in an oriented fashion. They are extremely flexible and capable of feeding a variety of parts and come equipped with a gear motor and a variable frequency controller.

Multiple belt conveyors are convenient for part removal from grinders, lathes, and other machinery. The use of a precision-machined side plate rather than an aluminum extrusion gives these conveyors a more rigid structure for increased operational life. The largest benefit of the multiple belt conveyors is that it allows coolant, lubricants, and metal chips to escape back into the machine and not on to the floor. The low profile side rails allow this conveyor to fit into the tightest spaces. This conveyor gives all the benefits of a flat belt conveyor without the downfalls.

FEEDALL Model 1680 Dual Round Belt Precision Conveyors:

- (1) Fixed Side Rail made from 1/2″ x 5″ precision machined #6061 Aluminum.

- (1) Removable Side Rail made from 12 ga. Cold Rolled Steel to allow easy access to all conveyor components for maintenance or upgrade.

- Conveyor drive is 130 VDC, 83 RPM, 1/12 HP Motor w/variable frequency controller.

- 2.5” Drive Pulley Diameter (direct drive).

- A variety of standard belt sizes and pulley spacings available to accommodate a wide range of part diameters.

- Cold Rolled Steel shafting and sealed ball bearings on all pulleys.

- 12” Belt Take-Up Capacity, centrally located so pulley distance remains constant.

OPTIONAL FEATURES:

- CINCINNATI-style mounting brackets are available for both entrance and exit end of the grinder

- Custom designed direct mounting plates available (for any type of machine)

- Floor support stands with optional linear bearings for wheel wear

Menu

Menu